We offer several methods to clean your Anilox roller.

Soda Blast cleaning

A proprietary sodium bicarbonate based media. It is classified as a food grade product and is 100% water soluble. This fracturing process down to 8 or 10 micron allows the blast media to clean to the bottom of the anilox roll cells. This is used to clean both ceramic and chrome anilox rollers.

A proprietary sodium bicarbonate based media. It is classified as a food grade product and is 100% water soluble. This fracturing process down to 8 or 10 micron allows the blast media to clean to the bottom of the anilox roll cells. This is used to clean both ceramic and chrome anilox rollers.

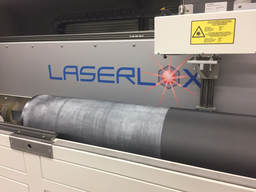

Laser cleaning

This roll was unsuccessfully cleaned with a competitor’s laser system for 24 hours. Then the customer sent the roll to us.

Their laser clean on the left; Laserlox™ clean on the right.

This roll was unsuccessfully cleaned with a competitor’s laser system for 24 hours. Then the customer sent the roll to us.

Their laser clean on the left; Laserlox™ clean on the right.

Brass Brush cleaning

A completely enclosed cleaning system which uses rotating brass brushes to safely remove dried ink and coating. This machine can be customized to fit your (6” X 44”) and (7.10” X 44”) roller sizes.

A completely enclosed cleaning system which uses rotating brass brushes to safely remove dried ink and coating. This machine can be customized to fit your (6” X 44”) and (7.10” X 44”) roller sizes.

Brass or Stainless Steel Brushes

Hand-held brushes can be used to spot clean the anilox roller. We recommend brass bristled brushes for chrome anilox rollers and stainless steel for ceramic anilox rollers.

Hand-held brushes can be used to spot clean the anilox roller. We recommend brass bristled brushes for chrome anilox rollers and stainless steel for ceramic anilox rollers.